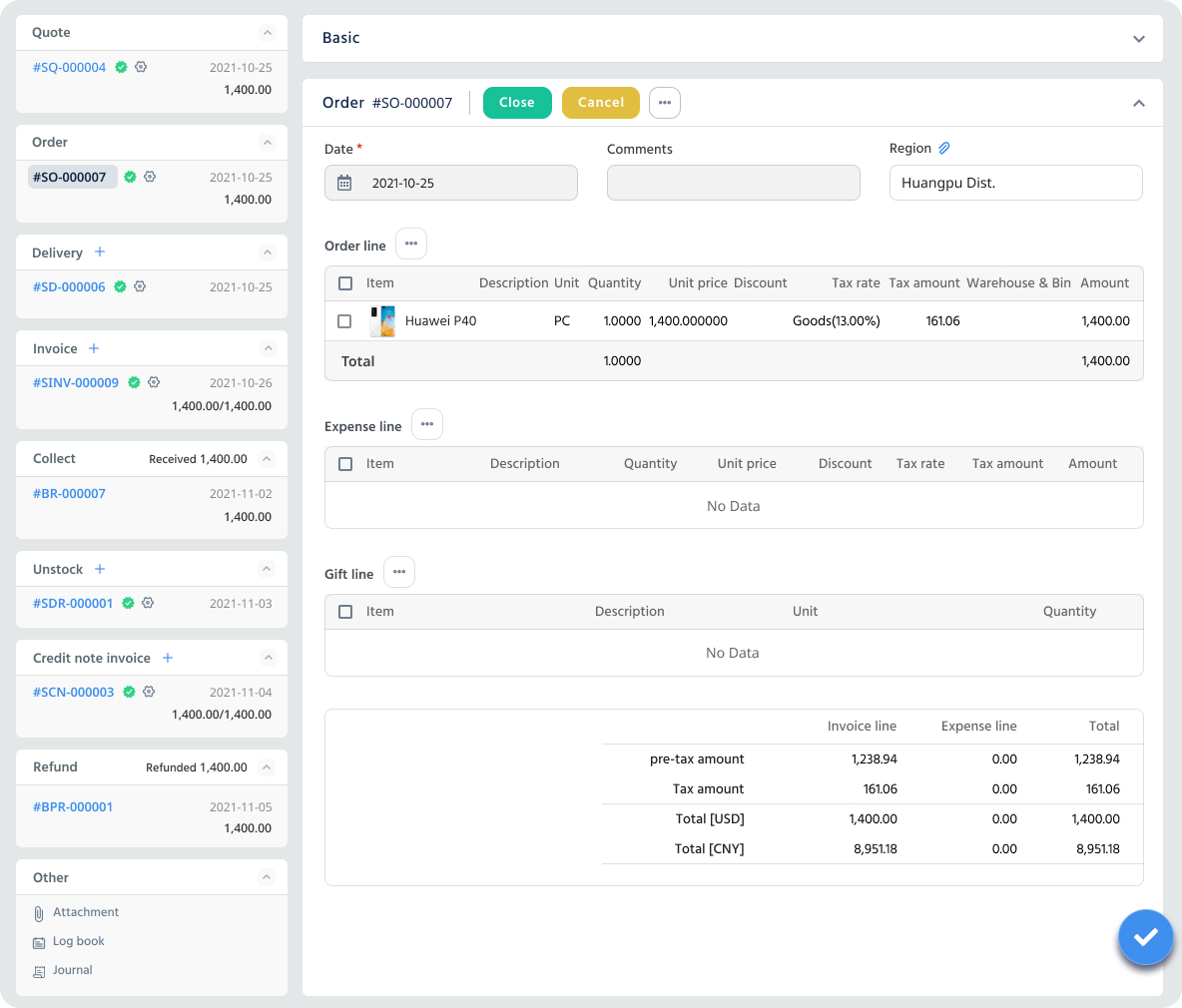

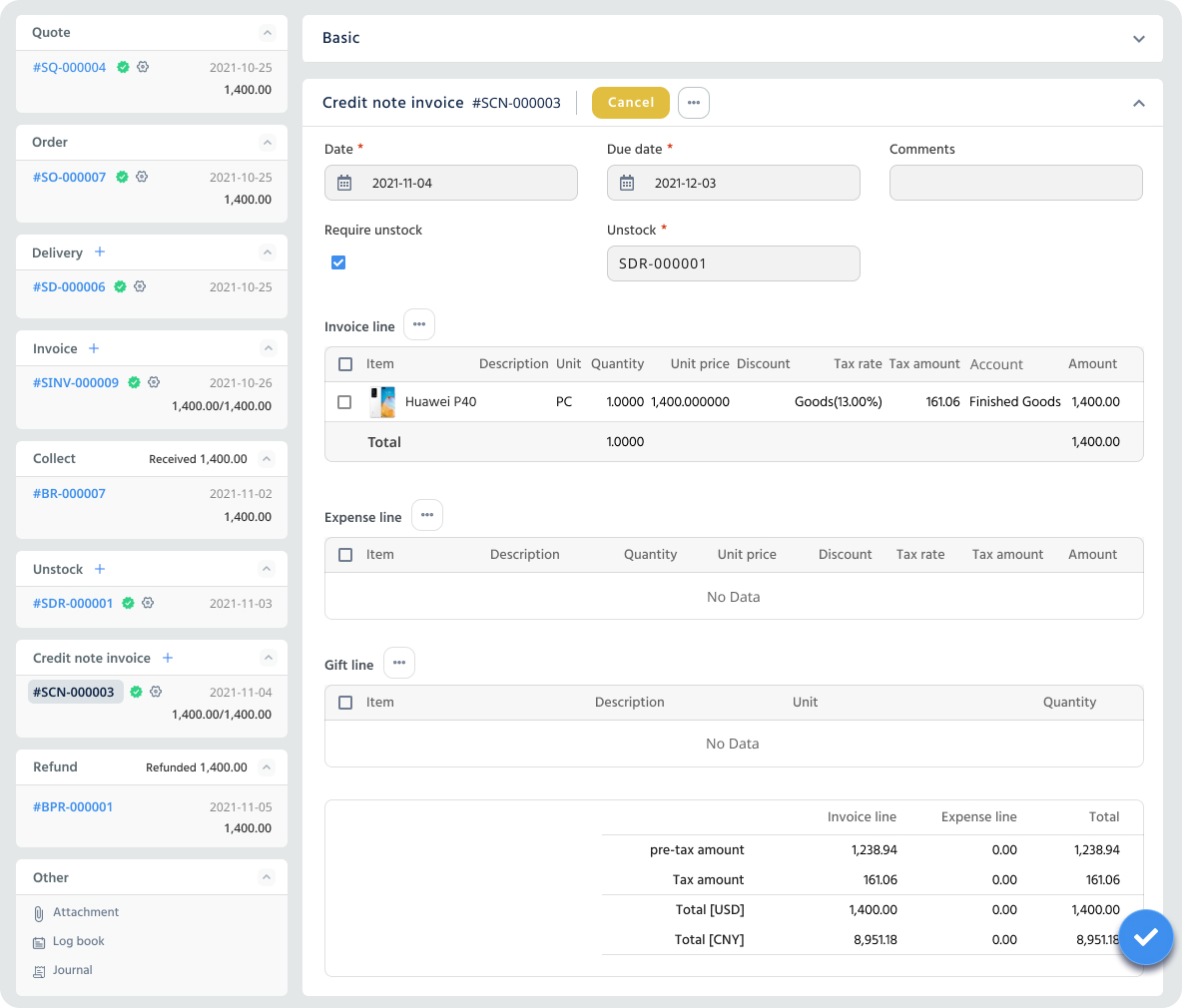

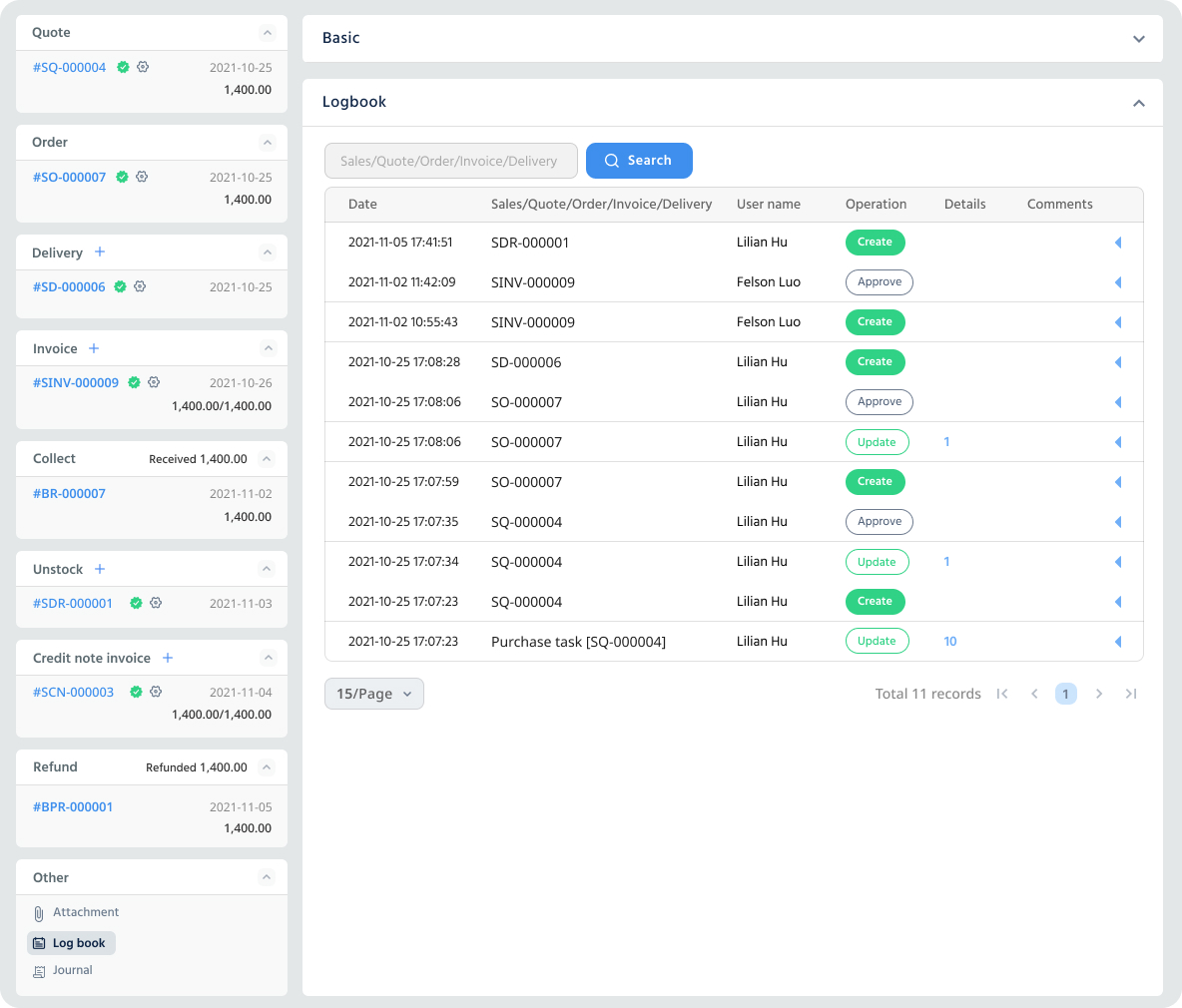

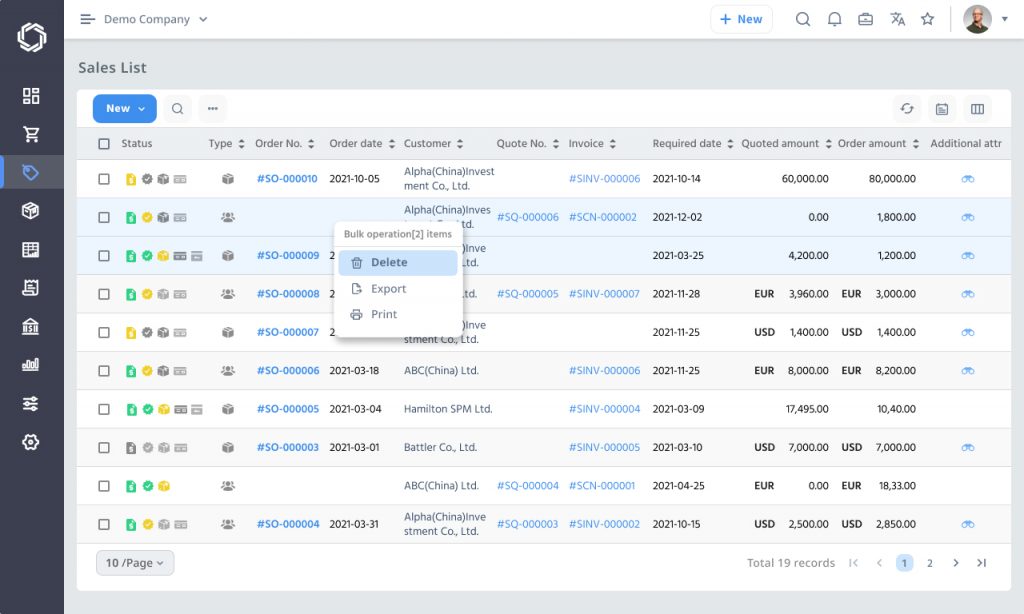

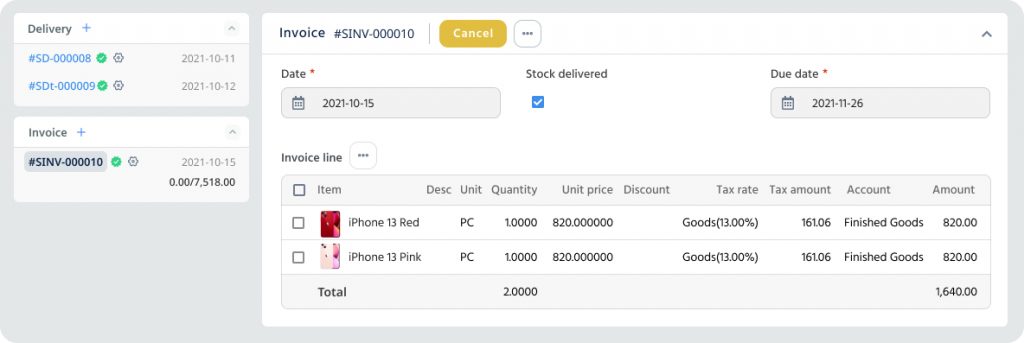

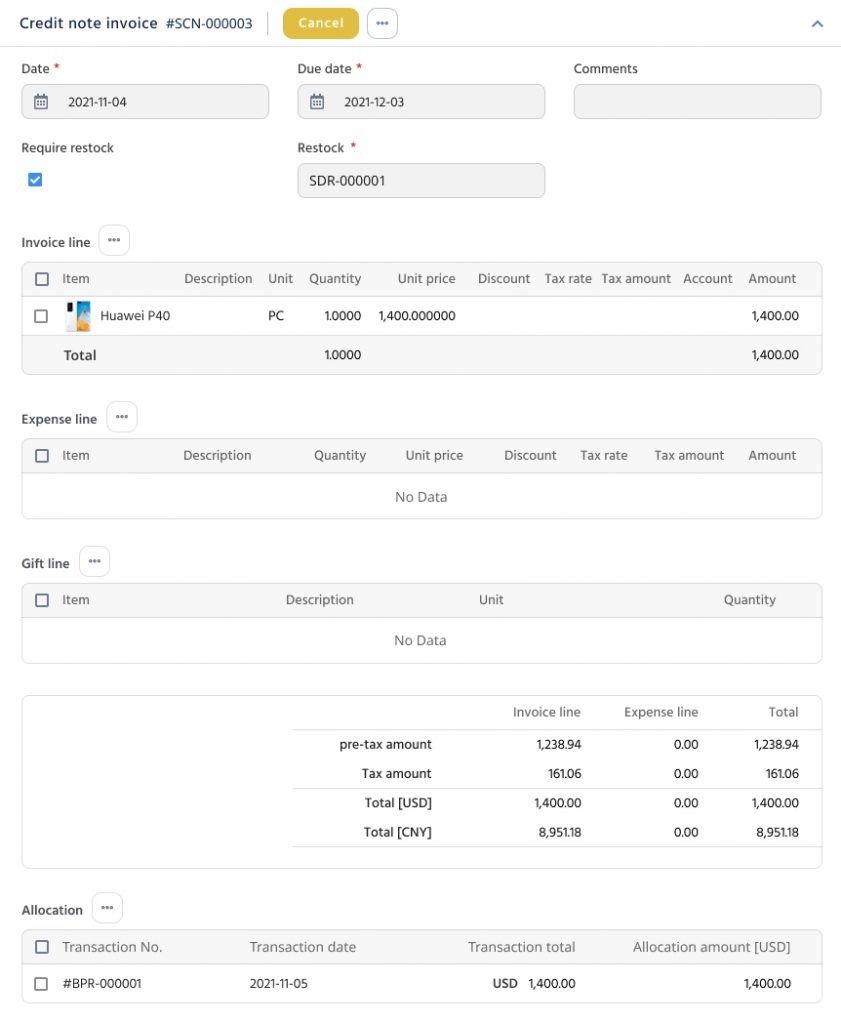

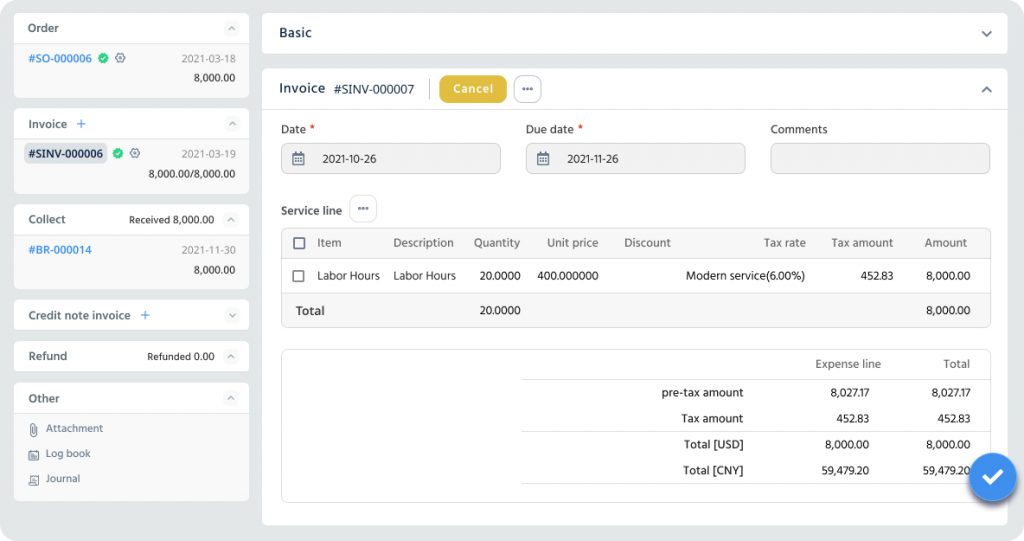

Sales

Streamline your sales order processing and tracking

Purchase

Streamline your purchase order processing and tracking

Product Management

Master information of products and services

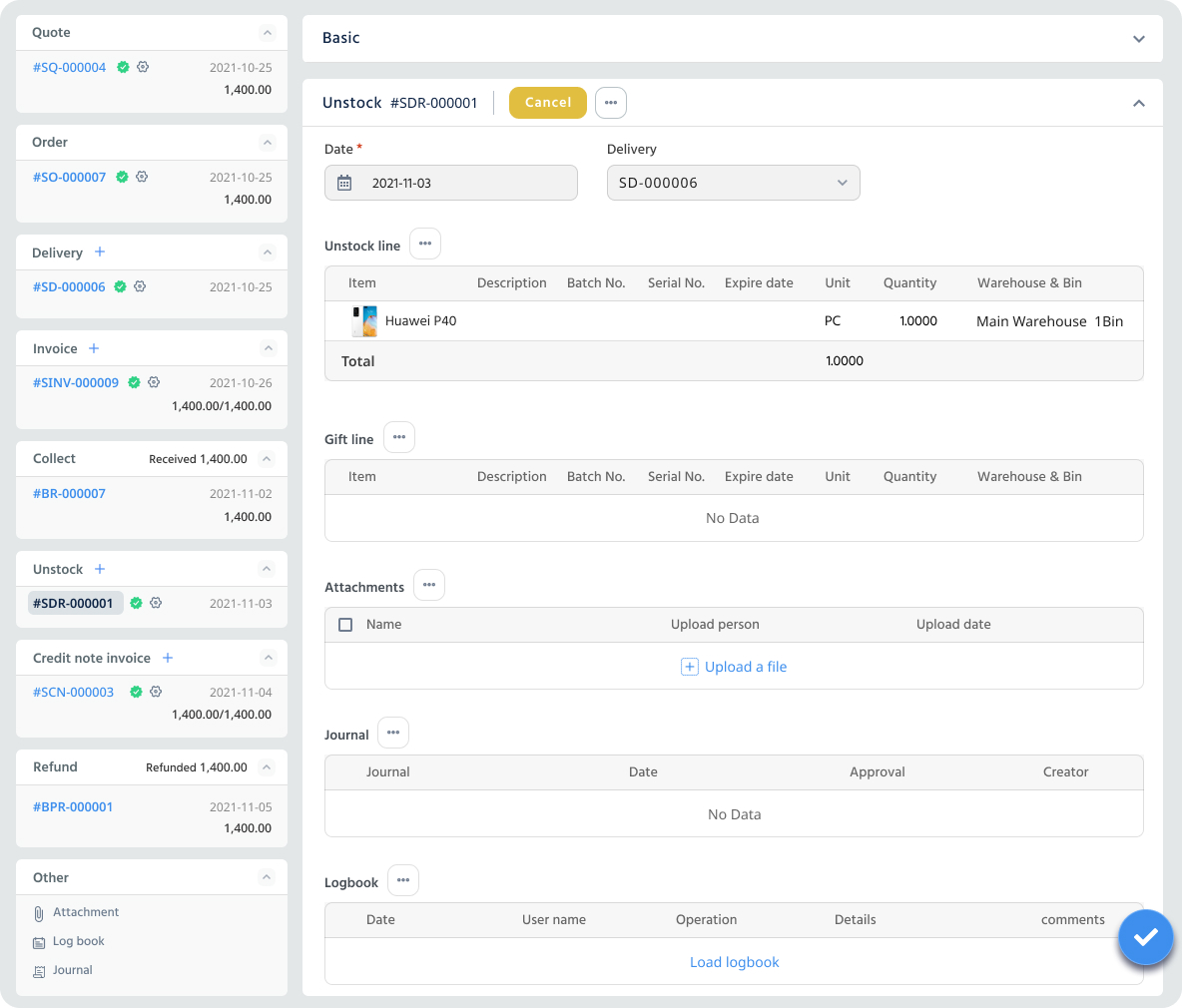

Inventory Management

Track and control your stock movement

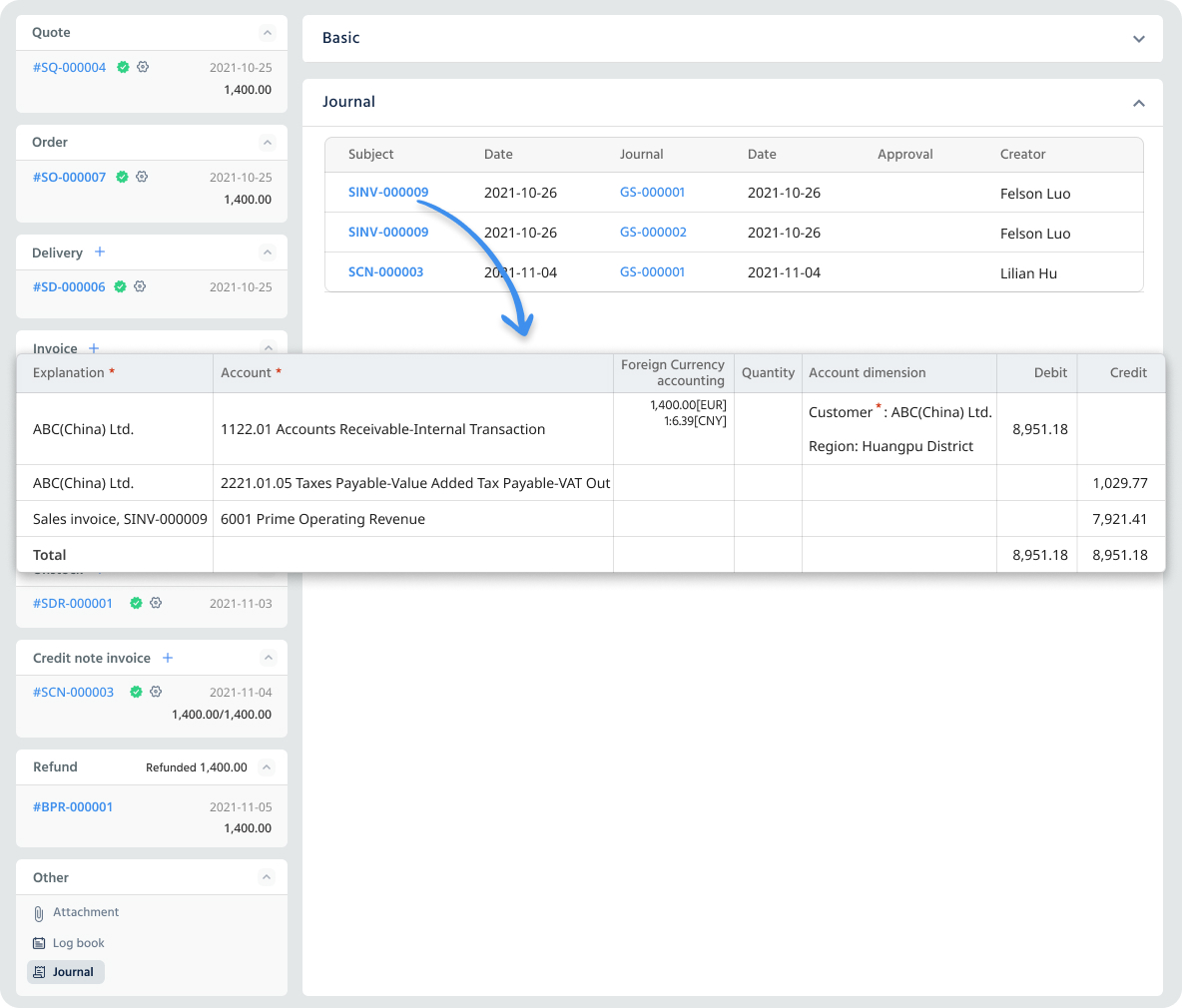

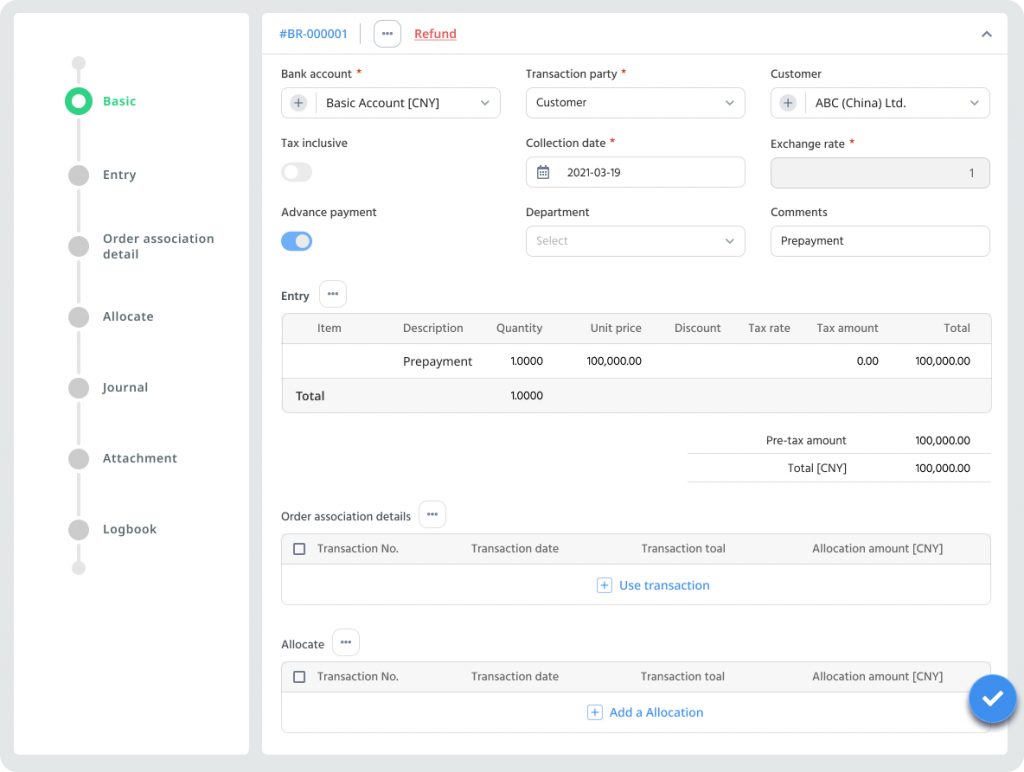

Accounting

Seamless integration between functional modules and general ledger

General Features

Features across modules and make Jeenie powerful

Production Management

Streamline your production operation and cost management

Subcontract Management

Streamline your subcontract procedures and cost management